A self-propelled mixer like TATOMA’s flagship model SUPERBMIX MBS-30 is something truly new on the mixer market. Due to its high capacity and efficiency, very few mixer wagon manufacturers in Europe have accepted the challenge of designing, manufacturing, and testing a machine of this size and characteristics, and only very large farms can truly see the benefits and economic savings of using this versatile tool. When fed to cattle, this extremely homogeneous mixture produced instantly improves their milk production and health. The machine is designed to process and dispense between 200 and 240 mix rations in just a few minutes.

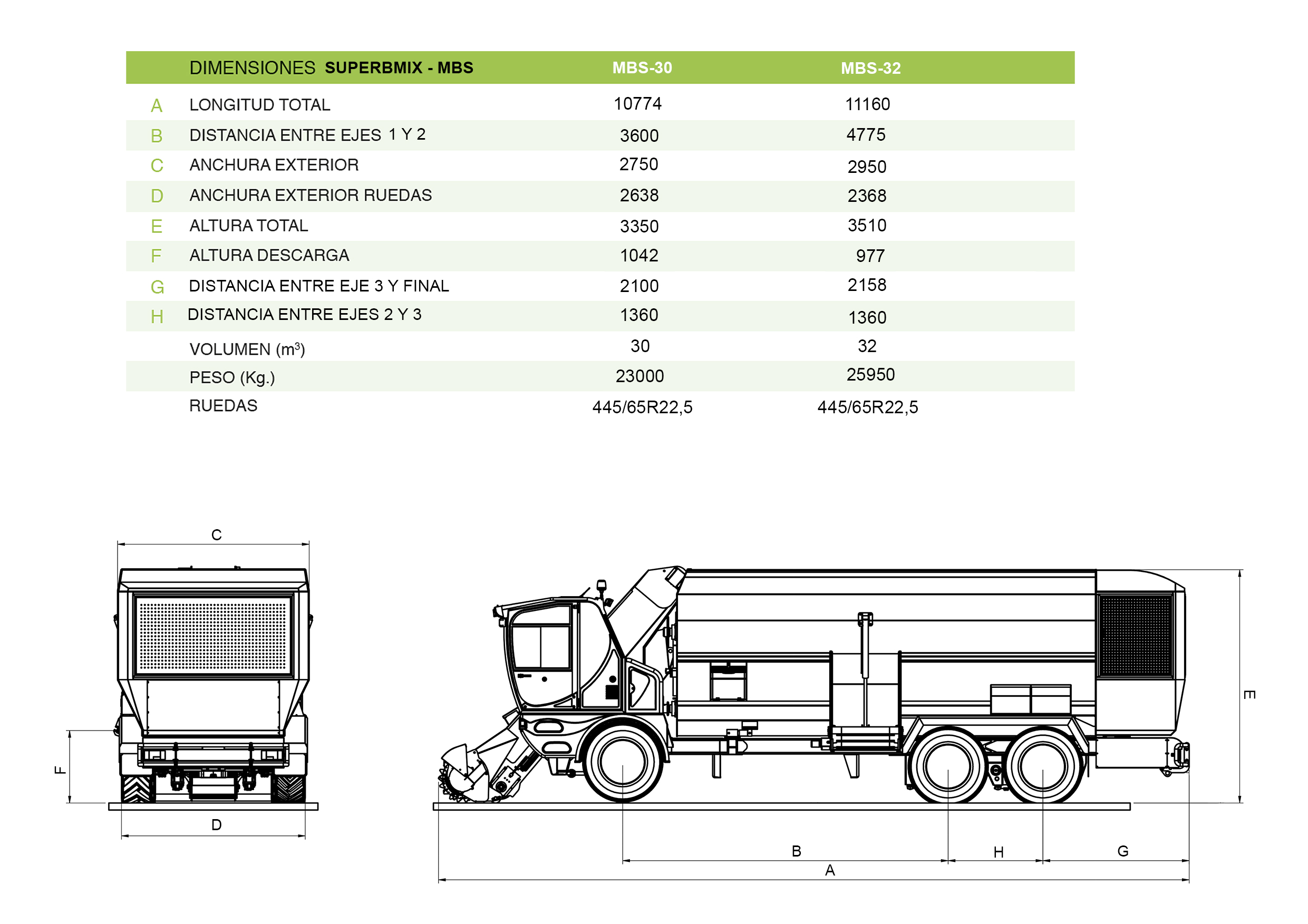

Two auger “SUPERBMIX” MBS 30-32

- 2 augers

- 180-195

- 5100x2750mm

Products / TMR Self-Propelled Mixers / TMR Horizontal Self-Propelled / Two auger “SUPERBMIX” MBS 30-32

Description ofTwo auger “SUPERBMIX” MBS 30-32

MÁS INFORMACIÓN

Si quieres saber más o pedir un presupuesto no dudes en consultarnos

MÁS INFORMACIÓN

Si quieres saber más o pedir un presupuesto no dudes en consultarnos

| TUB | 30 m3 |

| MIXER | Heavy-duty, highly resistant horizontal dual auger mixing system with interchangeable knives. Driven by two variable displacement pumps and two piston motors connected to the reducer at the rear. Adjustable mixing speed |

| CUTTER | 2 Motors, 225 CV horse power, adjustable speed. Width 2200 mm. Electrical lowering control from the control centre, lowering action cut-off with pressure switch to regulate the working pressure of the cutter. Driven by variable displacement pump and two orbital motors |

| DISCHARGE BELT | Rubber. Adjustable speed |

| DISCHARGING BELTS | Two side doors with discharge belt (see belt options). Width 990 mm |

| WEIGHSCALE | Programmable, 99 recipes x 20 ingredients X 10 discharges, modem output |

| ENGINE | SEE ENGINE TABLE |

| DIESEL TANK | 250 litres |

| TRANSMISSION | Closed circuit hydrostatic. Variable displacement pump and two piston motors, includes a device to ensure traction on the first and second axle when driving on difficult terrain |

| AXLES | Three, the first directional and driving, the second driving and the third directional. Six tyres 445/65R22.5 |

| SUSPENSION | Front hydraulic. Rear springleaf or rockerarm dual-axle |

| STEERING | Servo-assisted hydraulics on the first axle and forced on the third. Maximum turning angle 40º |

| . BRAKES | Service, parking and emergency on first and second axle |

| HYDRAULICS AND ELECTRICITY | Circuits designed for work in adverse environmental conditions. Compliant with European directives on machine safety and electromagnetic compatibility. Located behind the cabin |

| CABIN | One place. Made of steel with chemical anti-corrosion chemical treatment. Great visibility of the surroundings (inward slanted). Folding door. Safety glass |

| CONTROL SYSTEM | Electronic using programmable controllers. Multifunction joystick to control travel mode, loading and unloading. Digital display for viewing all machine parameters (hydraulic oil temperature, mixer pressure, cutter pressure, hydraulic oil level, emergency lights…) |

| EQUIPMENT | Two front work lights and two rear, CONFORT air suspension seat, fire extinguisher, hot water heating, radio CD, tool box, four-step ladder with platform |

| SPEED | Travel speed 0-30 km/h |