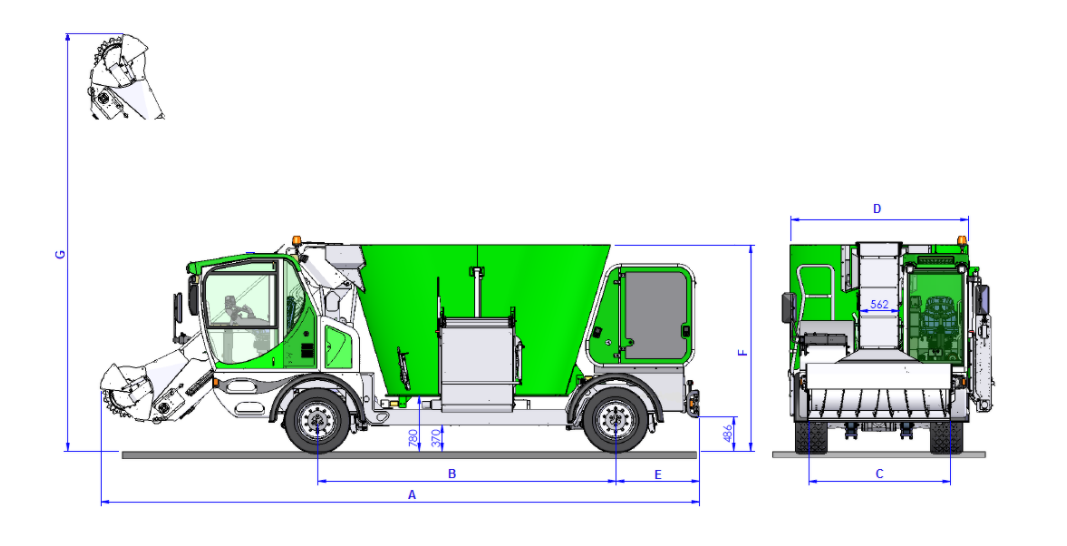

The MVS “ROUTERMIX-H” self-propelled mixer is designed to satisfy the demands of medium-sized farms, but with the benefits of machines developed to operate 8 to 10 hours per day with optimum comfort and efficiency. The location of the motor at the back of the machine provides for improved sight from the cab, and also places the driver further away from the source of noise, making their job significantly easier.

The 4-wheel steering and 4-wheel drive options have managed to make the ROUTERMIX-H a very manageable machine capable of manoeuvring in the most unfavourable conditions.

The single auger self-propelled vertical mixer adds to the advantages of the trailed vertical mixer the fact that it is completely autonomous, therefore removing the need for a tractor for moving or loading.

As in the case of trailed vertical mixers, its operation is based on a tapered-side tub and a conical auger that allows any type of product to be chopped and mixed.

The mixing is carried out by the effect of the multiple toothed knives of the auger, which cut the product while it moves upwards and falls again by gravity.

The machine incorporates a front cutting unit. This cutter by means of a conveyor belt, allows the products which make up the mix to be added into the tub.