The MTS LINCE self-propelled mixer fulfils the need for a dependable and more uniform horizontal mixing system based on a self-propelled machine. As a result, the machine is simple to construct, practical to use, and effective in its operation. The LINCE is the best equipment for medium- to large-scale farms since it has the benefits of the horizontal system in terms of mixing quality. Since there are fewer moving parts thanks to the single auger design, there is less chance of a breakdown, which makes maintenance easier.

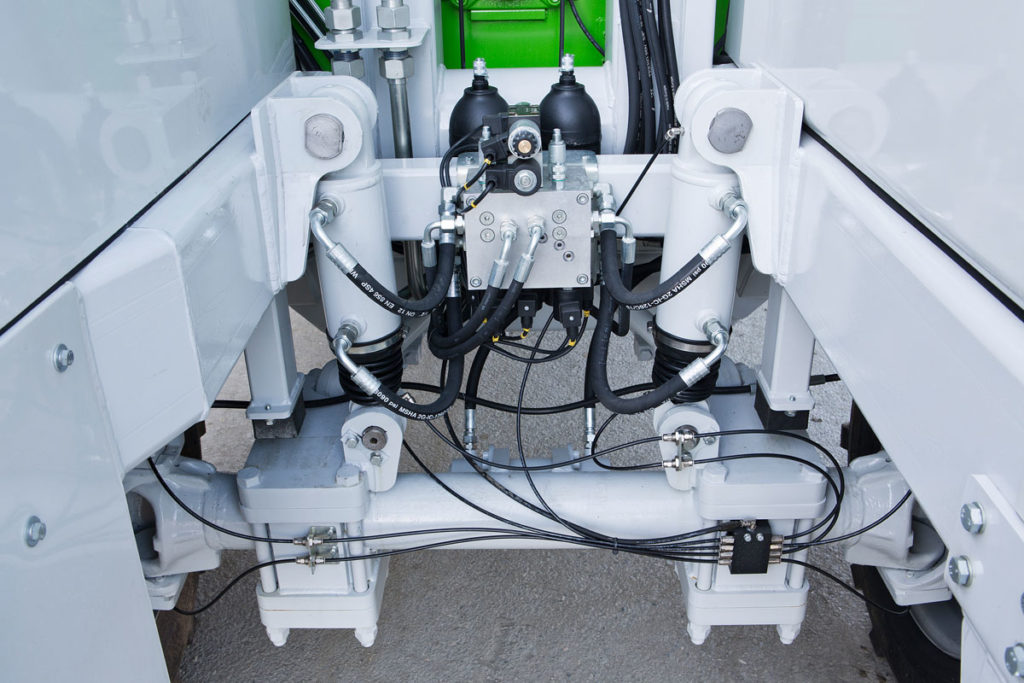

The mixing system, which consists of a non-continuous horizontal auger with hollow spirals in the centre, enables the product to flow lengthwise through the spirals and prevents the mixture from being compressed. In reality, we have two counter-rotating augers mounted on the same axis. This causes the mixture to move toward the centre, which makes it rise. With the help of the rotating blades mounted on the tank wall, the mixture is pushed toward the ends of the augers, closing the mixing circuit. A homogeneous, loose mixture is the end product, and the actual mixing time is decreased by 20%. The single auger concept minimizes moving parts, minimizing the risk of breakdowns and therefore facilitating maintenance. This revolutionary technology is PATENTED and represents an important technological advance in the preparation of feed rations.